GREVEN INSIGHTS CONSTRUCTION: Application parameters air void content / bulk density

In modern building material technology, material-specific properties are crucial for the quality and durability of buildings. Two particularly important parameters are the air void content and the bulk density. These parameters do not only influence the mechanical and physical properties of the material, but also significantly determine its processability and long-term behavior.

The air void content refers to the ratio of air-filled cavities to the total volume of a building material. Air voids occur as a natural consequence of the manufacturing process. However, their formation can also be specifically controlled by additives. An optimized air void content is particularly important for the freeze-thaw resistance of building materials such as concrete, as the pores act as an expansion cavity for freezing water and thus influence the formation of frost damage. At the same time, the content of air voids has a significant effect on the thermal insulation properties of building materials. More air voids, such as those found in lightweight concrete or aerated concrete, generally improve the insulating effect and make processing easier. Fewer air voids usually lead to a higher strength of the building material, but also to a correspondingly higher weight of the construction.

The bulk density, on the other hand, indicates the ratio of mass to the total volume of a building material, including all cavities. Both parameters are closely interrelated: a higher air void content generally leads to a lower bulk density. When selecting and developing building materials, it is important to find an optimum balance between these properties, depending on the application. Precise control and compliance with the specified values for air void content and bulk density is therefore a key aspect of quality assurance in the construction industry.

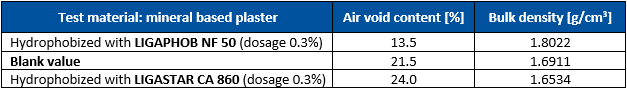

The selection of the right hydrophobing agent makes it possible to precisely adjust these parameters. With our unique combination product LIGAPHOB NF 50, air voids can be drastically reduced while generating a higher bulk density. LIGASTAR CA 860, on the other hand, significantly increases the air void content and reduces the bulk density of a mineral base plaster. This allows a building material to be variably adapted to the respective application needs - whether for building structures, thermal insulation or special applications.